In today’s construction landscape, PUF panels (Polyurethane Foam panels) have emerged as a revolutionary solution for building insulation. These versatile sandwich panels combine superior insulation properties with cost-effectiveness, making them increasingly popular in modern construction projects. Let’s dive deep into everything you need to know about these innovative building materials.

What Are PUF Panels?

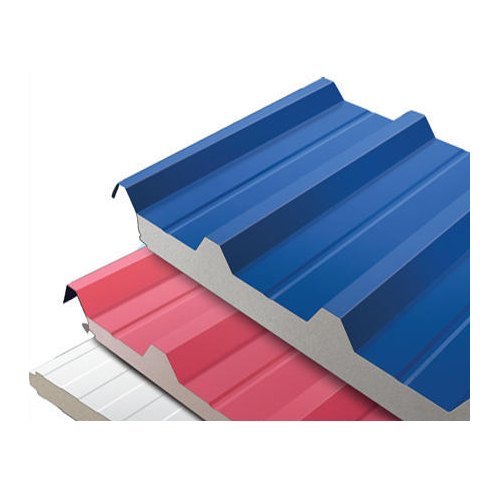

PUF panels, also known as insulated sandwich panels, consist of three main layers: two high-strength facing materials sandwiching a core of polyurethane foam. This unique construction creates a lightweight yet durable building material that offers exceptional thermal insulation properties.

Definition and Basic Components

A typical PUF panel comprises:

- Outer metal facings (usually steel or aluminum)

- Polyurethane foam core

- Protective coatings for weather resistance

The combination of these elements creates a robust insulated panel system that’s both practical and efficient.

Composition of PUF

The core material, polyurethane foam, is created through a chemical reaction between polyol and isocyanate. This reaction produces a dense, closed-cell structure that provides:

- Superior thermal resistance

- Excellent moisture barrier properties

- High structural stability

Benefits of PUF Panels

Superior Thermal Insulation

One of the most significant advantages of PUF panels is their exceptional thermal insulation properties. With R-values typically ranging from R-6 to R-8 per inch, these sandwich panels provide superior temperature control compared to traditional building materials.

Cost-Effectiveness

While the initial investment might be higher than conventional materials, PUF panels offer significant long-term savings through:

- Reduced energy costs

- Lower maintenance requirements

- Faster installation times

- Extended lifespan

Quick Installation

The modular nature of PUF panels allows for rapid installation, significantly reducing construction time and labor costs. A typical installation can be completed up to 50% faster than traditional building methods.

Applications of PUF Sandwich Panels

PUF panels find extensive use across various sectors:

- Cold Storage Facilities

- Temperature-controlled warehouses

- Food processing units

- Pharmaceutical storage

- Industrial Buildings

- Manufacturing facilities

- Warehouses

- Processing plants

- Commercial Spaces

- Retail outlets

- Office buildings

- Shopping centers

Technical Specifications

Thermal Performance

PUF panels typically offer:

- R-value: 6-8 per inch thickness

- Temperature resistance: -40°C to +80°C

- Thermal conductivity: 0.022-0.028 W/mK

Fire Safety

Modern PUF panels come with:

- Fire-retardant properties

- Class B fire rating

- Self-extinguishing capabilities

Installation Guide

Pre-Installation Requirements

Before installing PUF panels, ensure:

- Proper surface preparation

- Accurate measurements

- Appropriate tools and equipment

- Suitable weather conditions

Common Installation Mistakes to Avoid

- Incorrect panel alignment

- Improper sealing at joints

- Inadequate fastening

- Poor vapor barrier installation

Market Overview

The global PUF panel market continues to grow, driven by:

- Increasing demand for energy-efficient buildings

- Growth in cold storage facilities

- Rising awareness of sustainable construction

- Stringent building energy codes

Conclusion

PUF panels represent a significant advancement in building insulation technology. Their combination of superior thermal performance, ease of installation, and cost-effectiveness makes them an excellent choice for modern construction projects. Whether you’re building a cold storage facility or upgrading an existing structure, PUF panels offer a reliable, efficient solution for your insulation needs.

When selecting insulated panels for your project, consider factors such as:

- Specific application requirements

- Local climate conditions

- Budget constraints

- Installation expertise available

By carefully evaluating these factors and working with reputable manufacturers, you can ensure the successful implementation of PUF panels in your construction project.

ALPHA ROOFING 📞 Phone/WhatsApp: 7984365282 📍 Office: 136, Vihav Trade Center, Bhayli, Vadodara – 391410 🔗 Explore More: https://alpharoofing.in/puf-panel

Leave a Reply