The historic moon landing on July 20, 1969, was made possible by the integration of multiple cutting-edge technologies, including advancements in aerospace engineering, computing, and an innovative structural method known as sandwich construction. While most attention was given to rocketry and onboard systems, a crucial role was played by the structural design of the spacecraft itself.

A key breakthrough came in the form of sandwich technology, which allowed engineers to develop a spacecraft shell that was both lightweight and exceptionally strong. This structural efficiency was vital in withstanding the intense forces during launch, acceleration, and lunar landing.

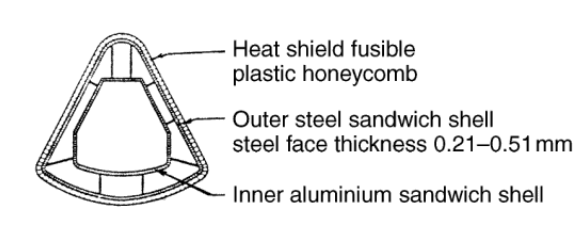

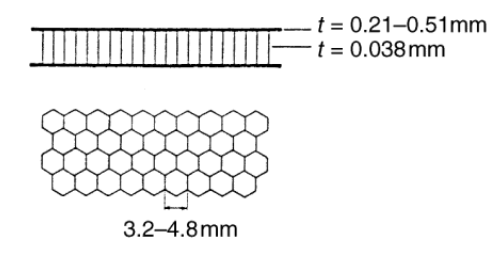

Illustration 1.1 highlights the layered structure used in the Apollo capsule, built using two interconnected sandwich shells. Illustration 1.2 focuses on the outer casing, made from dual steel face sheets encasing a honeycomb core. The core principle behind this construction lies in its ability to offer superior strength and stiffness while maintaining minimal weight—an essential requirement for space travel.

Sandwich construction of the Apollo capsule.

- Heat shield fusible plastic honeycomb

- Outer steel sandwich shell

Steel face thickness 0.21–0.51 mm - Inner aluminium sandwich shell

Cellular sandwich forming the outer shell of the Apollo capsule.

- t = 0.21–0.51 mm

- t = 0.038 mm

- 3.2–4.8 mm (cell width)

Before 1960, the use of sandwich technology was primarily restricted to aerospace projects. One of the earliest notable examples is the World War II Mosquito aircraft, frequently recognized as the first significant implementation of sandwich panels. However, even prior to that, there were various lesser-known but practical uses of the sandwich concept. Around 1960, the scope of applications began expanding rapidly, finding relevance in construction, cold storage, automotive design, and shipbuilding. This era also marked the onset of a global surge in the adoption of prefabricated components for a wide range of building and industrial purposes.

Leave a Reply